How to Better Forecast Demand in a Supermarket. Meet Inventory Optimization System.

Advanced data analytics and mathematical models help streamline the process of predicting demand and purchasing goods to the supermarket in the right quantity. This makes customers more likely to return because they always find what they need, and the store, in turn, increases revenue. Discover how modern inventory optimization systems work.

Challenges of the Inventory Planning and Management

Imagine a busy parent who regularly buys baby food at a nearby supermarket. If one day his kid’s favorite food run out, the irritated parent will go to another store. If the situation continues, the customer will simply change the supermarket to one where he buys everything he needs in one go.

Another situation is an excess of products in the store. It’s not uncommon for them to land in the store’s aisles and make it difficult for customers to move freely with a shopping cart. (or a baby stroller).

If there are shortages on the shelves, the store loses customers and thus revenue. In a situation of overstocking, the problems are bigger than just annoyed customers – it’s unnecessary involvement of capital, high-interest rates when buying goods on credit, risk of overdue and disposal of unsold products.

On top of all this, there are changing market conditions, seasonality, different buying patterns of customers and a mass of other factors that need to be considered in sales forecasting.

Fortunately, predictive analytics comes to the rescue, making it possible for automated merchandise order management systems to order products in the right quantities.

Different Forecasting Models

Supermarkets have been using various forecasting and inventory management systems for years. Unfortunately, these systems are often flawed – they order too much or too little goods. Some are unable to learn and take into account the rapidly changing environment – rising inflation, changing customer tastes, seasonality, weather, days of the week, etc. As a result, they require periodic adjustments by a dedicated specialist.

On the other hand, there are modern solutions that allow the system to learn on an ongoing basis and do not require as frequent involvement from machine learning specialists. Some products may have seasonal demand, fortunately, algorithms can quickly analyze dozens of factors, discover complex relationships and thus effectively forecast supply and demand.

How Does the Inventory Optimization System Work

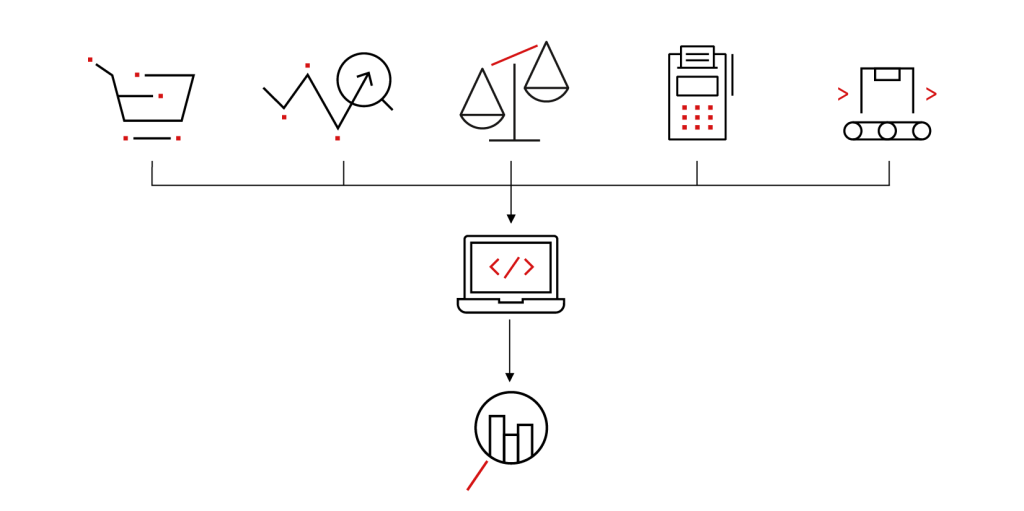

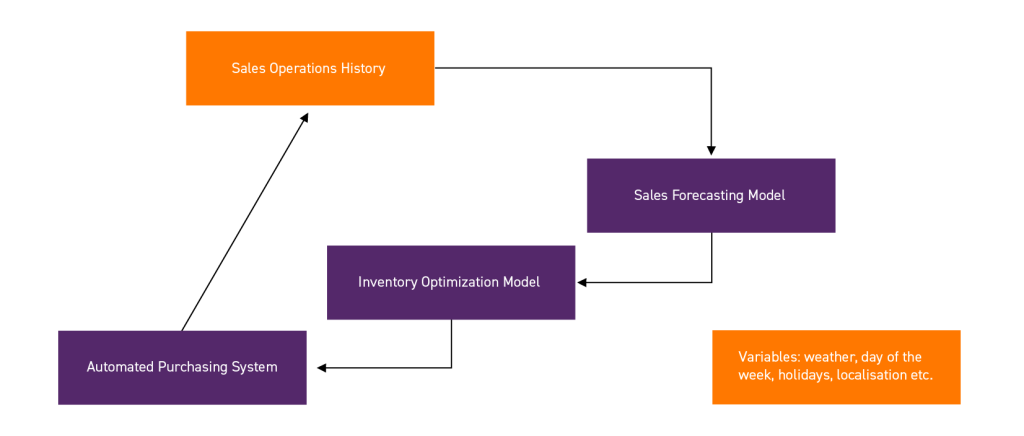

The inventory optimization system is based on the use of three independently operating mathematical models.

1. Sales Forecasting Model

The most important model is a forecasting model based on time series regression. It seems complicated, but in fact it is based on analyzing sales operations from previous years.

In this model, it is important to combine specific days or short terms with analogous terms and days from previous years. Extremely important in this model are weather data, holidays and events that affect the sales process. In this type of time series analysis, the inclusion of days of weeks and hours is also crucial. The forecasting model, based on the calendar, previous years’ sales and weather forecasts, can very accurately predict sales of specific product groups in the short term.

2. Inventory Optimization Model

This model is built in operations research methodology. It is based on available retail space and shelf display guidelines. The inventory optimization module is essential, as it must result in the delivery of the right number of goods at a certain point in the future so that the inventory level is optimal. In practice, it looks like this: the first sales forecasting model sends information to the optimization model, which dynamically calculates what the level of goods in the store should be. Then it sends the information to the third module – the order processing.

3. Automated Purchasing System

Sales chains have been using automatic order processing systems for years. The difference here is that the system orders goods based on information from the forecasting model and the optimization model. If the orders cannot be fulfilled within the timeframe specified by the earlier models, the purchasing system sends information to the second module to re-optimize the inventory.

In summary, the first forecasting model predicts future sales and sends information to the second model – which optimizes inventory. The third model is responsible for automatic orders. In this approach, the threat of too much or too little stock is reduced. As we mentioned, too much stocking leads to losses from unnecessarily involved capital and losses in the form of expired products. In turn, too few goods in the store leads to an increase in the probability of lost potential sales.

How to Implement a Complete Forecasting, Optimization and Ordering System

Implementing a complete ordering system requires adequate preparation on both the store side and the implementation team side.

1. Understanding the real need of the customer.

In-depth discussions with analysts on the development team’s side allows for the proper identification and naming of needs.

2. Initial data analysis by the implementation team.

Specialists check what data the retail network has and whether it is appropriate for the project.

3. Creation of a project charter, i.e. a project definition.

This document defines the scope of the project and milestones so that everyone understands exactly what will specifically come out of the development work at each stage.

4. Detailed analysis

A thorough examination of the data and capabilities of each of the three models.

5. A workshop with the client where the final design is worked out.

6. Project execution

7. Maintenance, which is the maintenance of the procurement infrastructure.

Summary

Investment in self-learning algorithm-based forecasting and inventory management systems is a competitive advantage and an increasingly popular trend. Predictive analysis is a task in which an automated system that can adjust itself to rapidly changing factors is far superior. Optimal procurement means increased profit and reduces the risk of impairment.

Need more info on inventory optimization system? Let’s talk!