Application of Artificial Intelligence in Optimizing the Supply Chain of Building Materials

Can artificial intelligence revolutionize the management of building materials supply chains? Learn how AI can help optimize demand forecasting, manage orders and inventory, minimize risks, and personalize customer offerings. Discover the future of AI in the construction industry.

The supply chain in the building materials industry is a complex and multifaceted process that encompasses everything from sourcing raw materials, through production and warehousing, to the distribution of finished products to end customers. Effective management of this supply chain is crucial for ensuring continuity of supply, minimizing costs, and maximizing profits. In the era of digitalization and dynamic market changes, traditional supply chain management methods are becoming insufficient. Artificial intelligence is emerging as a powerful tool that can revolutionize the way construction companies manage their resources and logistical processes. In this article, we will explore how AI can impact the optimization of the supply chain in the building materials industry, the benefits it brings, and the challenges companies may face when implementing these modern technologies.

What is a supply chain?

A supply chain is a comprehensive system that encompasses all stages of production and distribution of products, from sourcing raw materials, through production processes, transportation, and warehouse management, to delivering finished products to the end customer and post-sales service. In the building materials industry, the supply chain is particularly complex due to the diversity and specificity of products that need to be delivered to construction sites at the right time and in the right quantities.

What are the stages of the supply chain?

1. Sourcing Raw Materials

The first stage of the supply chain is sourcing raw materials. In the building materials industry, this includes purchasing raw materials such as cement, steel, wood, sand, and other necessary materials for production. At this stage, it is crucial to establish relationships with reliable suppliers who can provide the right quality and quantity of raw materials at competitive prices. This process also requires monitoring raw material markets and managing risks associated with their availability and prices.

2. Production

The next stage is production, where raw materials are processed into finished building products such as bricks, drywall, pipes, or windows. The production process can involve various operations, including mechanical, chemical, and thermal treatment. It is essential to optimize production processes for efficiency and quality, which can be achieved through the use of modern technologies and automation.

3. Warehousing

After production, finished products are stored in warehouses. Warehouse management includes optimizing inventory placement, monitoring stock levels, managing warehouse space, and order fulfillment. Ensuring appropriate storage conditions is key to avoiding product damage and maximizing warehouse space utilization. Warehouse Management Systems (WMS) and technologies such as the Internet of Things (IoT) can significantly improve the efficiency of this stage, thereby reducing storage costs.

4. Distribution

The distribution stage involves transporting products from warehouses to sales points or directly to customers. Optimizing delivery routes, managing the transport fleet, and monitoring transport conditions are crucial for ensuring timely and quality deliveries. Timeliness is especially important in the construction industry due to tight project schedules.

5. Sales and Customer Service

The next stage is product sales and customer service. Managing customer relationships, processing orders, handling complaints, and ensuring high customer satisfaction are key at this stage.

6. Returns and Complaints Management

The final stage of the supply chain is managing returns and complaints. In the building materials industry, this may include returns of damaged or incorrect products and handling customer complaints. Effective management of this stage is crucial for maintaining customer satisfaction and minimizing financial losses.

Optimizing the supply chain is crucial for the operational efficiency and profitability of companies dealing with building materials. An optimized supply chain minimizes costs, shortens order fulfillment times, increases product availability, and improves customer service quality. Introducing artificial intelligence into this process can bring revolutionary changes, enabling better resource management, demand forecasting, and automation of many logistical processes.

Find out how a new B2B platform can increase your sales. Download the e-book!

What are the Supply Chain Strategies?

1. Lean Strategy

The Lean strategy focuses on eliminating waste and maximizing the value delivered to the customer. In the context of the building materials supply chain, this strategy includes actions such as optimizing production processes, reducing excess inventory, and minimizing order fulfillment times. Key elements of the Lean strategy are:

- Inventory Control: Maintaining minimal inventory levels to reduce storage costs and the risk of obsolete products.

- Process Optimization: Utilizing techniques such as Just-in-Time (JIT) to deliver materials exactly when needed, eliminating waste and increasing efficiency.

- Continuous Improvement: Regularly analyzing and improving processes to eliminate waste and enhance quality.

2. Agile Strategy

The Agile strategy focuses on flexibility and the ability to quickly respond to changing market conditions. In the building materials industry, where demand can be variable and dependent on many external factors, the Agile strategy is particularly important. Key elements of the Agile strategy are:

- Flexibility in Production: The ability to quickly adjust production processes to changing market demands.

- Quick Response to Changes: The ability to rapidly respond to demand changes, supplier issues, or other unexpected events.

- Close Collaboration with Customers: Regularly gathering feedback from customers and adjusting the offerings to meet their needs.

3. Hybrid Strategy

The hybrid strategy combines elements of both Lean and Agile strategies to gain the benefits of both approaches. In the context of the building materials supply chain, this strategy involves optimizing production processes and inventory management (Lean) while maintaining flexibility and the ability to quickly respond to market changes (Agile). Key elements of the hybrid strategy are:

- Supply Chain Segmentation: Dividing the supply chain into segments that can be managed using different strategies based on the specifics of the products and markets.

- Balanced Inventory Management: Maintaining appropriate inventory levels to reduce costs while ensuring flexibility in responding to demand changes.

- Technology Integration: Utilizing advanced technologies such as AI and IoT to monitor and optimize processes in real-time.

4. Sustainable Development Strategy

The sustainable development strategy focuses on minimizing the negative impact of the supply chain on the natural environment and on corporate social responsibility. In the building materials industry, this strategy includes actions such as:

- Eco-friendly Sourcing of Raw Materials: Choosing suppliers who use sustainable practices in sourcing raw materials.

- Reduction of CO2 Emissions: Optimizing production and transportation processes to minimize greenhouse gas emissions.

- Recycling and Reuse of Materials: Implementing recycling practices and reusing building materials.

How Can AI Support the Optimization of Processes in Supply Chains?

Demand planning

Accurate demand forecasting is the foundation of effective inventory management. Inaccurate forecasts can lead to excess inventory or shortages, impacting costs and operational efficiency. In the building materials industry, where demand can be seasonal and variable, accurate forecasts are particularly important.

Trend Analysis by AI

AI, using advanced algorithms, can analyze historical data and current market trends, allowing for more accurate demand planning. These algorithms can consider various factors such as seasonality, changes in customer preferences, and macroeconomic data.

AI can analyze the impact of external factors such as changes in trade policies, weather conditions, or global economic events on demand forecasts. This enables companies to better prepare for unexpected market changes. For example, AI can incorporate weather forecasts, which can affect the pace of construction work and consequently the demand for building materials.

Automating the Ordering Process with AI

Artificial intelligence enables the automation of the product ordering process, speeding up order fulfillment and minimizing the risk of human errors. AI systems can automatically create orders based on demand forecasts and current stock levels.

AI algorithms can be used to optimize delivery schedules, select the most advantageous suppliers, and monitor order fulfillment in real-time. For example, algorithms can analyze delivery costs and lead times to choose the best suppliers, leading to significant savings.

Optimizing Inventory Placement and Warehouse Management with AI

AI supports the optimization of inventory placement in warehouses, allowing for better space utilization and reduced order fulfillment times. This helps reduce storage costs and increase operational efficiency.

AI systems can monitor stock levels in real-time, detecting shortages or surpluses and automatically taking corrective actions. This helps avoid costly production downtimes or excessive inventory, which can lead to financial losses. For example, AI can automatically generate replenishment orders when stock levels reach a certain threshold.

AI helps optimize logistical processes by evaluating and selecting the best suppliers based on multiple criteria such as price, quality, delivery timeliness, and collaboration history. This enables companies to work with the most reliable suppliers, resulting in higher service quality and lower costs.

Integration of AI with Other Systems

fIntegrating AI with ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), PIM (Product Information Management) and WMS (Warehouse Management System) enables the automation of many business processes and better coordination of activities across the enterprise. This provides a comprehensive view of the company’s operations and facilitates more informed decision-making.

Integrating data from various sources allows AI algorithms to conduct more comprehensive analyses, leading to more accurate recommendations and better decision-making. For example, integrating sales, inventory, and production data enables better inventory management and production optimization. This helps reduce operational costs and increase profits.

How AI can help identify and minimize risks in the supply chain optimization

Historical Data Analysis

AI can analyze historical data to identify patterns and trends that may indicate potential future risks. For example, analyzing historical data on equipment failures can help predict when and where future failures might occur. This allows companies to take proactive measures to prevent downtimes and minimize risks.

Real-time Monitoring and Response

AI systems can monitor the supply chain in real-time, detecting anomalies and immediately responding to potential threats. For example, using IoT, AI can monitor temperature and humidity in warehouses to ensure that building materials are stored under appropriate conditions. If deviations from the norm are detected, the system can automatically send alerts to the relevant personnel to take corrective actions.

Simulations and What-If

Scenarios AI can conduct simulations and analyze various “what-if” scenarios to help companies prepare for potential threats. For example, AI can simulate the impact of a key supplier’s shutdown on the entire supply chain and propose alternative solutions. This helps companies better prepare for unexpected events and minimize their impact on operations.

Personalizing Offers – Tailoring Products and Services to Individual Customer Needs with AI

Customer Data Analysis

Artificial intelligence enables construction companies to collect and analyze vast amounts of customer data, allowing for a better understanding of their needs and preferences. Analyzing demographic data, purchase history, website behavior, and customer service interactions helps create detailed customer profiles. This allows companies to segment their customer base and tailor offers to specific audience groups. For example, AI can identify that a certain group of customers prefers eco-friendly building materials, enabling targeted promotional offers.

AI algorithms can analyze current market data, weather forecasts, construction trends, and other variables to adjust prices, discounts, and promotions in the most attractive way for customers. For example, during peak construction periods, AI can automatically increase the availability of popular materials and offer special discounts to loyal customers. Dynamic offer adjustments enhance the company’s competitiveness and maximize profits.

Dynamic Pricing and Discount Adjustments Based on Data Analysis

AI allows for dynamic pricing and discount adjustments based on market data analysis and competitive strategies. AI algorithms can analyze production costs, transportation costs, and other factors affecting margins to determine optimal prices that maximize profits. For example, AI can detect that demand for certain building materials is higher during a specific time of year, allowing for price increases and higher margins. Conversely, during periods of lower demand, the system can suggest price reductions to boost sales and minimize inventory surplus.

Personalized Recommendations and Customer Service

AI can also support offer personalization by generating product and service recommendations that best meet individual customer needs. AI-based recommendation systems analyze purchase history and customer preferences to suggest products that may interest them. For example, if a customer regularly buys paints and painting tools, the system can suggest new products in that category or special promotional offers. Additionally, AI-powered virtual assistants can support customer service by answering questions, helping select products, and tracking order status. This provides customers with personalized and efficient service, increasing their satisfaction and loyalty to the company.

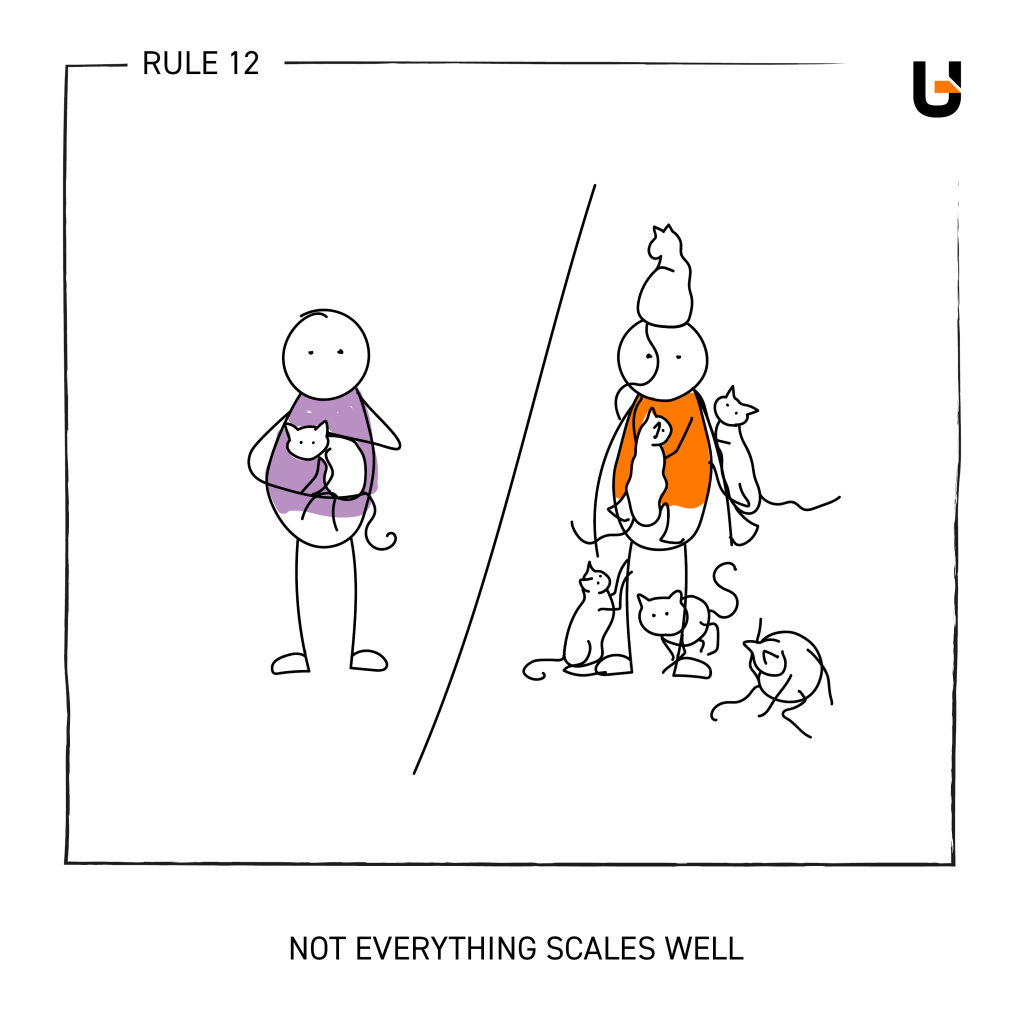

Challenges and Limitations in Implementing AI Solutions in the Supply Chain Optimization

Technological and Organizational Challenges

Implementing artificial intelligence in optimizing the supply chain comes with several technological and organizational challenges. One of the main issues is the need to integrate AI with existing systems such as ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), and WMS (Warehouse Management System). This process can be complex and time-consuming, requiring significant financial investments and specialized technical knowledge.

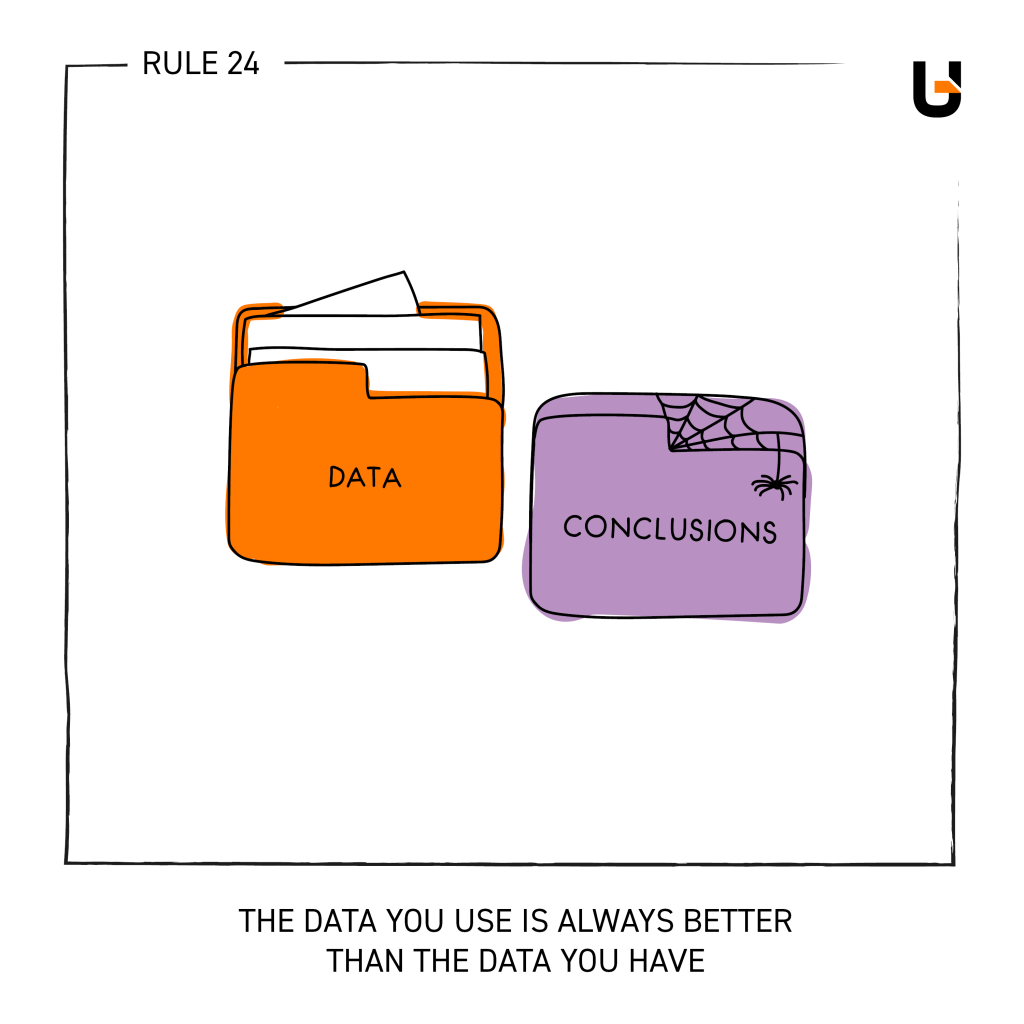

Data Quality and Availability

AI relies on analyzing large datasets, so the quality and availability of this data are crucial. Companies often face issues with incomplete, inconsistent, or outdated data, which can affect the accuracy of forecasts and decisions made by AI systems. Businesses must invest in appropriate tools for collecting, storing, and processing data, which may involve additional costs.

Implementation and Maintenance Costs

Implementing AI involves high initial costs, including the purchase of hardware, software, and employee training. Additionally, maintaining and updating AI systems also generates costs. Companies must be prepared for long-term investments that do not always yield immediate benefits.

Employee Resistance and Organizational Culture

Introducing AI into logistical processes may encounter resistance from employees who fear job loss or changes in their duties. Changing organizational culture and convincing employees of the benefits of AI can be a difficult and time-consuming process. Companies must invest in training and educational programs to help employees understand and embrace new technologies.

Data Security and Privacy

The use of AI also involves data security and privacy issues. Companies must ensure adequate safeguards to protect data from unauthorized access and cyberattacks. Compliance with data protection regulations, such as GDPR (General Data Protection Regulation), is essential to avoid legal sanctions and loss of customer trust.

Perspectives and Development Directions of AI in the Building Materials Industry

The application of artificial intelligence in optimizing the supply chain of building materials brings a number of significant benefits that can revolutionize logistics management in this industry. AI enables precise demand forecasting, which allows for better inventory management and cost minimization. Automating the ordering process, dynamically adjusting prices and discounts, and optimizing delivery routes are just some aspects where AI can significantly improve operational efficiency. Additionally, AI supports offer personalization, tailoring products and services to individual customer needs, increasing their satisfaction and loyalty.

However, implementing AI in the supply chain also comes with certain challenges. Integrating AI with existing systems such as ERP, CRM, and WMS, ensuring the quality and availability of data, and the costs of implementation and maintenance are the main difficulties that companies must face. Moreover, changing organizational culture and convincing employees of the benefits of AI may require time and investment in training.

Despite these challenges, the future of AI in the building materials industry is extremely promising. The continued development of technologies such as the Internet of Things (IoT) and machine learning opens up new possibilities for optimizing and automating logistical processes. Companies that decide to invest in AI can expect significant improvements in operational efficiency, cost reduction, and increased competitiveness in the market.